Electrospinning Medical Device: Bioresorbable Electrospun Nonwovens From Concept to Product

Synthetic polymer-based textiles have been used for medical applications for decades and represent a staple production technique on par with injection molding and machining. Textiles are provided in a number of techniques, such as knits, braids, woven fabrics, monofilaments, films, and various nonwovens. For many medical applications, however, traditional textiles do not meet performance requirements. Melt blown nonwovens, for example, require heating a polymer to high temperatures which can damage the polymer chains and prevent inclusion of heat sensitive drugs. A solution to this issue, first developed in the early 1900s but which has gained considerable interest in the last several years, is a dry-spinning technique called electrospinning.

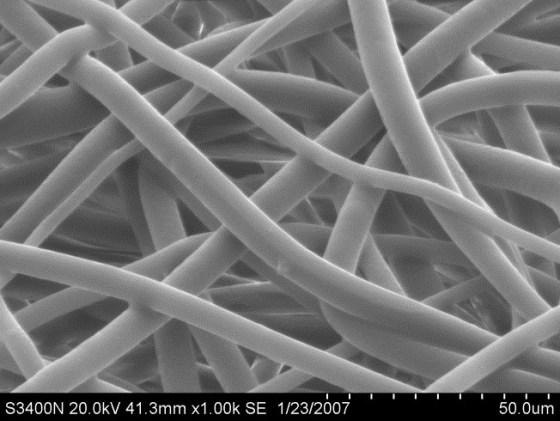

Electrospinning (typically) involves the injection of a polymer solution into a high voltage static electric field, which draws the injection stream into fibers with very small diameters on the scale of nanometers (10-9 meters) to micrometers (10-6 meters), which is similar to human cell types such as fibroblasts. The resulting fabric can be up to 90% free volume with low pore size and high surface area. The small fiber dimensions also create unique mechanical behavior.

Textiles created from electrospinning have potential medical applications for active and directed wound healing applications, stent grafts, surgical mesh, adhesion prevention, and tissue separation. Also, because the process is most often performed at room temperature, drugs and other heat sensitive materials can be included in the spinning solution and dispersed throughout the fibers.

Poly-Med has been creating electrospun textiles for various medical applications for more than 10 years, and has developed the equipment and in-house expertise to meet the most stringent product demands. We have produced fabrics utilizing hazardous organic solvents such as hexafluoroisopropanol (HFIP) and many polymers including polyglycolide, polylactide, polydioxanone, polycaprolactone, and various copolymers.

To support our customers, Poly-Med has scaled our capabilities to include tight environmental controls and significant production throughput. This coupled with our ISO 13485/9001 quality system and vertically integrated contract development and manufacturing services, gives our partners the advantage of unique materials and processes created in a compliant atmosphere.

Let us know how our experience and capabilities can help you develop your product. Please contact us or visit us at www.poly-med.com

M. Scott Taylor, Ph.D.

Leave a Reply

Want to join the discussion?Feel free to contribute!