Poly-Med CTO, Scott Taylor, recently contributed to a panel discussion at the MedTech Conference. The article below summarizes the panel discussion.

Panel says 3-D printing opens many possibilities in med-tech production

Medical Device Daily – 10/2/17

by Katie Pfaff

SAN JOSE, Calif. – 3-D printing is a much lauded technology, but does it offer real benefits in med tech? Panelists at the Advanced Medical Technology Association’s MedTech Conference session “Printing the future: 3-D printed today, tomorrow and beyond” discussed implications of printing with 3-D in medical device manufacturing.

Framed as a follow-on session from a discussion the prior year of regulation and 3-D printing, moderator Allison Shuren, partner, Arnold and Porter Kaye Scholer LLP, spoke with industry panelists about the promise of 3-D in creating medical devices, and what may be on the horizon. Shuren discussed a general example of 3-D printing in which a Hornbill bird at the National Zoo in Washington, D.C., was provided a printed beak so that it was able to feed and survive. The beak was created through a collaboration between the Smithsonian Institute and the Museum of Natural History, the latter of which provided the skeleton of a Hornbill from its archives to provide basis material for 3-D printing.

Elle Meyer, director, life sciences, Carbon, then discussed the benefits of additive manufacturing compared to traditional manufacturing, which she saw as three-fold.

“The first reason, which may be obvious, is that it creates opportunities not available in traditional manufacturing, or that would be prohibitively expensive,” she said.

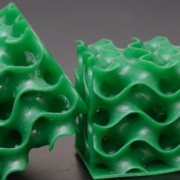

Additive manufacturing introduces possibilities such as lattices which could not be produced otherwise, as well as patient-matched items which improve comfort and effectiveness like orthodontic appliances, hearing aids or CPAP masks, she said. Secondly, additive manufacturing allows for smaller manufacturing opportunities when a device is needed. Third, additive manufacturing can lead to cost reduction through cost-effective low-volume production, improving processes, time-reduction and removing complex steps.

Regulatory perspective

Dennis Hahn, director, regulatory policy innovation, Ethicon and vision care, Johnson and Johnson, noted that regulators are addressing the uptick in what may be referred to as “customized devices,” and the FDA does already address such med tech.

“We are very fortunate in the U.S. to have a very specific definition for a custom device,” said Hahn.

Customized devices are defined as those manufactured for individuals, created by prescription and used or distributed through a health care practitioner, and are limited to no more than five per year, he said. However, items like 3-D printed devices or devices with 3-D components, would more likely be handled differently.

“Really what we are looking at in customized device – patient specific device, patient matched device, personalized device are all same. In the U.S. these are not customized devices, they’re different, and our regulatory approval pathway is determined by how you define those fixed dimensions and parts that are customized,” said Hahn.

Manufacturers would seek an approval based on fixed aspects of the device and a range for customization in a similar manner that contact lenses are approved with a set diameter of the lens and a range of prescriptions or powers depending on patients’ sight needs. Europe is more complex with rules that customized devices cannot be mass-produced while Australia, Brazil and other markets have no definition for customized devices.

Devices to improve response

Scott Taylor, CTO, Poly-med Inc. talked about applications for 3-D printing which allow for enhanced capabilities in medical devices.

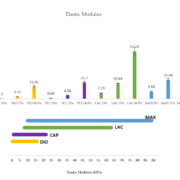

“What we’re seeing is the body is filled with these tailored structures that are not necessarily patient specific. Bone, other tissues, they have all these extracellular components that are far beyond the capabilities of what we can do,” said Taylor.

Instead of building patient-specific devices, 3-D printing can be used to build “tiny structures to encourage a specific response” like healing or tissue growth.

“We have a much better understanding behind the biologics of these injuries [hernias, for one] and to reconstruct them,” said Taylor. “And now we finally have this microscopic ability to create structures and create surfaces that can elicit that type of response. That’s ultimately where we want to be.”

He pointed to hernia mesh to promote healing or orthopedic devices that initiate bone growth in addition to surgical placement of a plate and screw. Additive manufacturing also presents an opportunity to streamline processes, he said, reducing multistep processes to one that can incorporate a high-level of complexity.

Metal manufacturing and 3-D

Jonah Meyerberg, co-founder and CTO, Desktop Metal, moved the conversation to how additive manufacturing applies in metal medical devices.

“The medical sector is very well positioned for additive manufacturing in general and additive manufacturing of metal is not an exception,” said Meyerberg. “The complex shapes you are able to create and the properties of metal really allow additive manufacturing to apply geometries that are modeled after biological geometries and environments like never before. And the relatively small production volumes and custom parts, additive makes it economical in a way it was not before.”

3-D printing can accommodate custom shapes and greater complexity.

He also added medical devices had lead an entry into 3-D printing with polymer usage in hearing aids to customize shapes into the ear canal, and in orthodontic appliances like custom-made trays. Meyerberg said 3-D applications in metal devices have not yet been fully realized, highlighting as an example orthopedic implants with porous areas encouraging tissue to grow into the device.

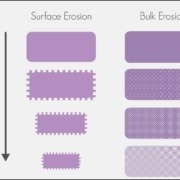

When asked if the new methods introduced problems for regulatory bodies, Meyer commented industry was steadily validating the materials or additive manufacturing methods, and that FDA would evaluate using their “same toolkit.” As with any medical device, those made using 3-D printing would be evaluated to determine if the process is replicable, the device is biologically compatible, manufacturing methods meet quality standards, and ultimately that the device is effective and safe in its intended use.