Biomedical Textile Processing: Heat Setting Impact on Materials Properties

If you’ve ever woken up late for an important job interview or meeting, you’ve probably thrown on some clothes and looked in the mirror with horror at all of the wrinkles staring back at you. While ironing clothes is certainly not one of my favorite chores, something about the heat and steam can totally change the outfit’s look. In medical textiles, this process of heat setting is equally important…and not just to look good in the operating room!

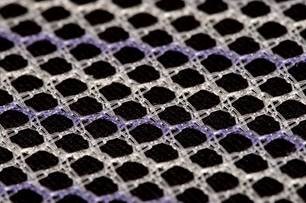

At Poly-Med, Inc., we synthesize very unique polymers for extrusion into fibers/yarns and ultimately for knitting into specialized medical textiles. Though the material coming off of the knitting machine looks somewhat finished, the process to manufacture a useful product is often far from done. One such post-processing technique we use is known as heat setting. Though our materials are medical grade and bioresorbable, the core chemistry at work with heat setting our advanced textiles is the same as with ironing common clothing materials.

The long, polymeric chains in both synthetic clothing and our bioresorbable polymers are able to “stick” together to produce fibers by means of intermolecular forces, namely hydrogen bonds. When exposed to moisture, pressure, and/or temperature, these intermolecular bonds can break, shift, and realign to produce unwanted creases. Even without the externally added forces, internal stresses are introduced throughout processing, such as from the twisting of yarn during spinning or the bending of the yarn during knitting to produce the pattern.

To work around this and remove the internal stresses, the fabric can be heated above the Glass Transition Temperature (Tg), where amorphous regions of the polymer can easily slide around. This temperature is below the Melting Temperature (Tm) and thus does not result in a phase change of the fabric, but merely provides enough energy to break down the intermolecular forces in the amorphous region which previously formed into now undesirable positions. As the material cools back down, the intermolecular forces can stabilize into stress-free conditions for whatever configuration the fabric is currently held in. For clothing with a heavy iron on top of it, the result tends to ‘press’ out the wrinkles and flatten the fabric between the flat ironing board and iron.

It is here, in the actual processing methods, that differences arise for our unique materials. In clothing, a particularly pesky wrinkle can be conquered with the addition of steam and a little elbow grease. The addition of water easily penetrates the amorphous regions of the fibers and acts as a plasticizer or lubricant between the polymeric chains, effectively reducing the material’s Tg to allow the amorphous regions more freedom to move. When the material hydrolytically degrades, as with our bioresorbable polymers, the addition of steam isn’t such a great idea. We instead use dry heat, forced air, and even vacuum chambers to apply heat to the fabric and still avoid degradation or strength loss. Heat Setting by these means further allows us to use custom fixtures and presses to hold the fabric in place as it cools, producing flat as well as 3D fabric forms. While this does make the medical textiles look great, the process often improves function as well, improving handle-ability for downstream processing and end-use, allowing the construct to conform to a unique shape, providing dimensional stability, and also increasing temperature resistance.

Though bioresorbable polymers pose a few unique challenges for heat setting, Poly-Med is very experienced in unique solutions for both small and large scale projects. If you are interested in post-processing of medical textiles or you are working on a medical device and are interested in learning more about bioresorbable polymers, Contact us today to learn how we can advance your idea.

Andrew Hargett, M.S.