Electrospinning for Bioresorbable Medical Devices

Electrospinning Overview:

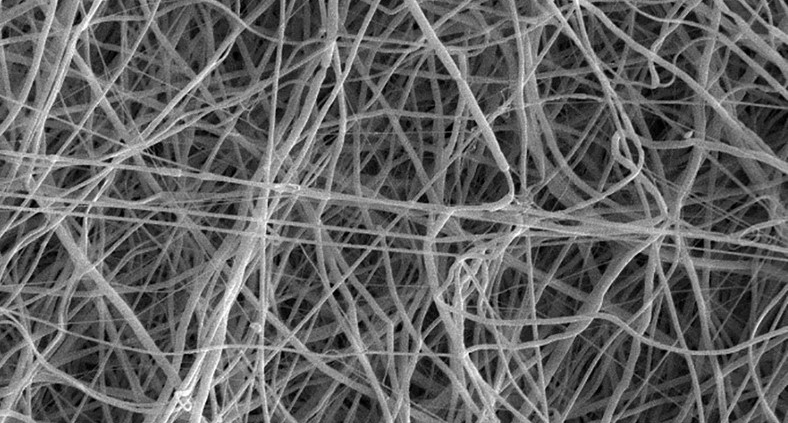

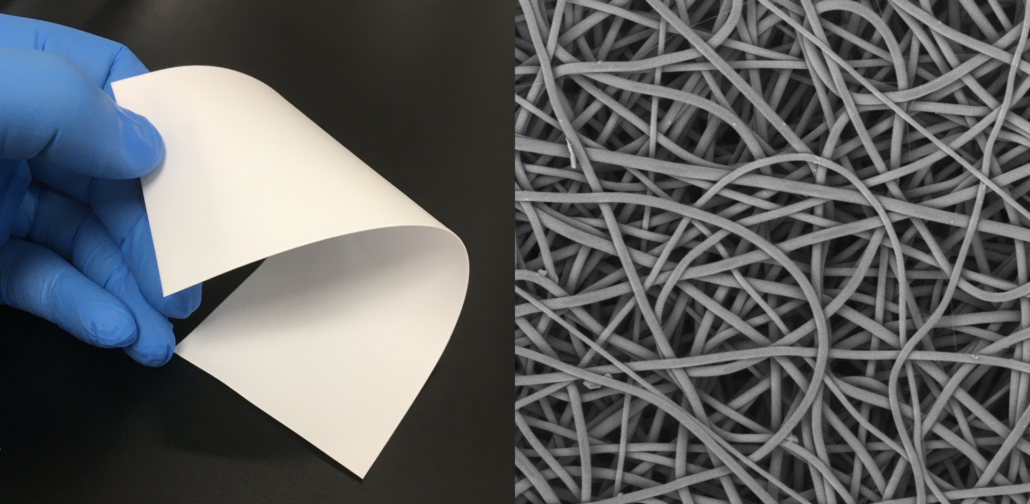

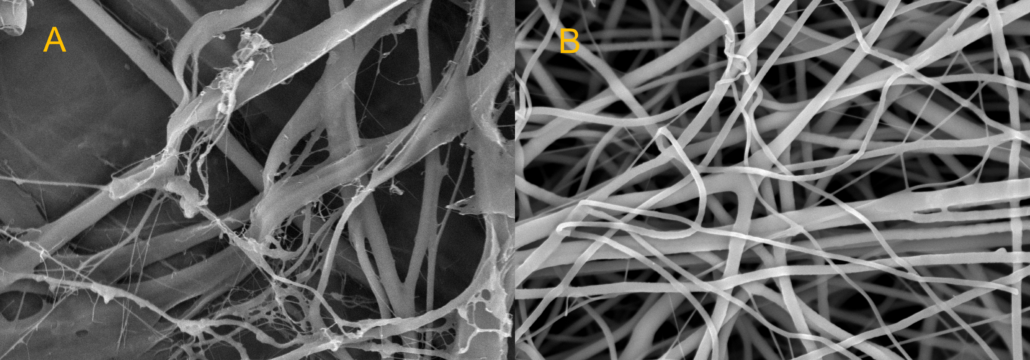

Electrospinning is a fiber production method which uses electric force to draw charged threads of a polymer solution or melt into fibers with diameters in the nano to micron size-scale. Electrospinning in currently being utilized in disciplines ranging from regenerative medicine (i.e., vascular, tendon/ligament, cardiac, neural, and wound healing), nanomedicine/drug delivery, cancer therapy, dentistry, and biosensors.

The set-up is simple and straightforward and includes three (3) main components:

1. Spinneret: A pump/polymer feed that distributes a polymer solution/melt at a controlled flow rate

2. High voltage source: Electrical force is applied to the spinneret, which accelerates the polymer solution as a jet from the spinneret tip to the collecting target

3. Collecting target: Accumulation area for fibers to build a fibrous construct, it can be designed for various applications and fiber orientation specifications (i.e., drum, blade collector, metallic plate, and array of parallel or counter electrodes)

Electrospinning results in continuous fibers that can be produced to submicron architectures, and exhibit high surface area-to-volume ratios and inter-/intra porosity. The electrospinning technique also allows for control over mechanical properties, microstructure, degradation rates, and downstream cellular and tissue level responses. Combining these benefits with the advantages of bioresorbable materials and devices can yield positive patient outcomes including but not limited to:

• Eliminating the need for invasive secondary surgery intervention since the bioresorbable polymer is metabolized via physiological biochemical pathways

• Providing porous, supportive scaffolding for cell guidance, migration, and development until natural tissue replaces the implant/device

• Imitating structural tissue complexity by being able to build structures from the nano, micro, and macro-scale

• Synthetic alternative to acellular dermal matrices derived from human or animal-based tissues

Poly-Med, a leader in bioresorbable polymers, has utilized electrospinning to develop bioresorbable scaffolds and devices for improved tissue regeneration, restoration, and function. Poly-Med has the ability to provide industrial scale electrospinning services for a range of bioresorbable polymers that meet not only mechanical and degradation requirements but are produced with controlled processes in a cGMP environment.

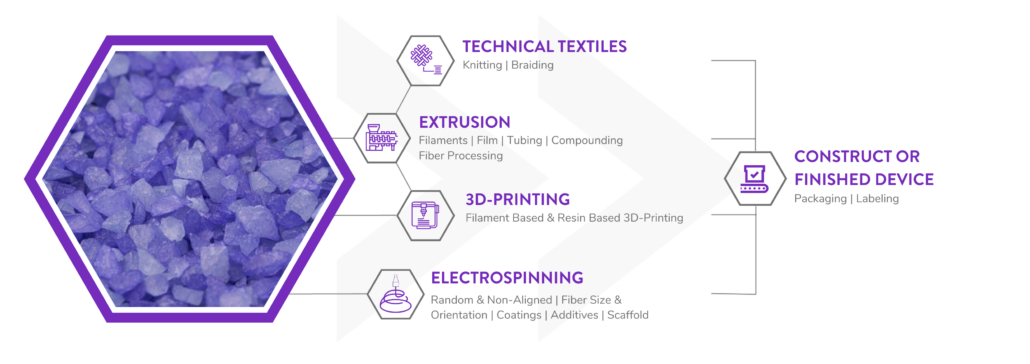

Poly-Med is a Vertically Integrated Bioresorbable Medical Device Manufacturing Partner:

Manufacturing bioabsorbable medical devices is hard. Controlling moisture levels and material degradation through the production cycle requires specialized equipment and process controls to ensure quality of finished devices. In contrast to other bioresorbable polymer manufacturers, Poly-Med produces polymer, is able to extrude this material to desired monofilament or multifilament formats, and is able process this material via warp knitting, weft knitting, or braiding processes to produce custom biomedical textiles. Beyond traditional textiles, we can process our bioresorbable polymers into non-woven formats via electrospinning via our state-of-the-art electrospinning facility. In addition to accessing Poly-Med’s more than thirty (30) years of experience manufacturing bioresorbable polymers, partnering with Poly-Med simplifies your bioresorbable medical device manufacturing supply chain. Contact us to today begin developing your custom bioresorbable medical device product line with a trusted partner for manufacturing advanced bioresorbable medical devices or purchase off-the-shelf high-performance bioresorbable polymers!