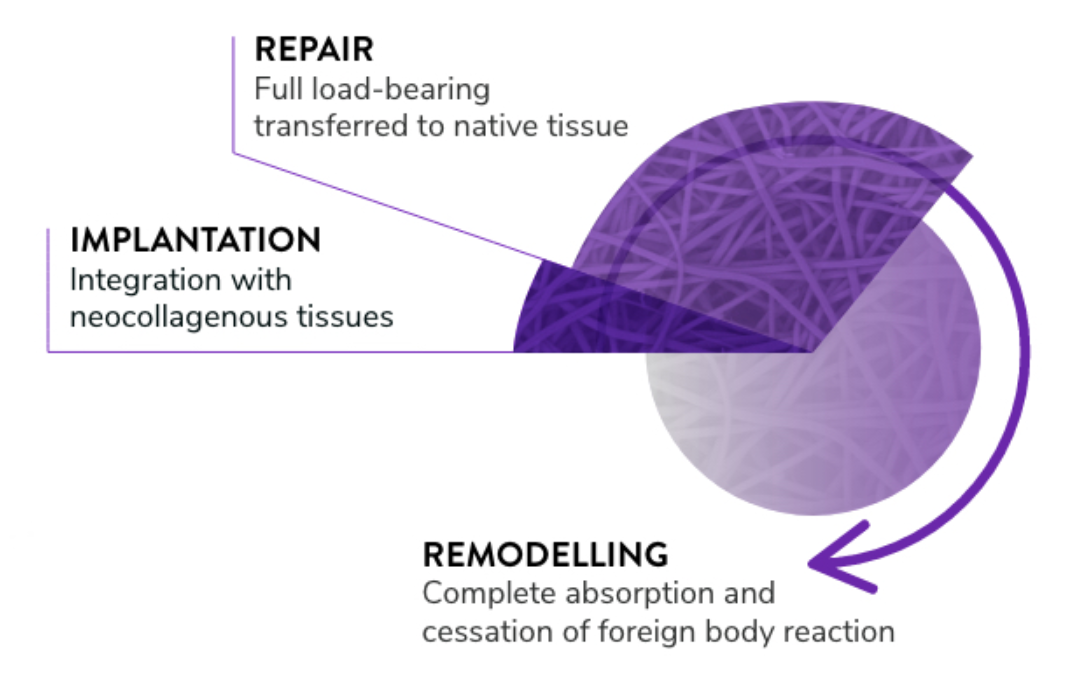

Advanced Absorbable Implants.

BIORESORBABLE SOLUTIONS DELIVERED

Materials, devices, and delivery materials that work with the body for better, faster outcomes

Advanced Absorbable Implants

BIORESORBABLE SOLUTIONS DELIVERED

Materials, devices, and delivery materials that work with the body for better, faster outcomes.