News

Insights from the leaders in design and production of bioresorbable products.

Insights from the leaders in design and production of bioresorbable products.

https://poly-med.com/wp-content/uploads/2024/01/Fiber-1.png

2227

3361

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

poly-med2023-09-01 11:44:122024-01-24 17:53:20Bioresorbable Polymer Extrusions of Yarns, Fibers, & Films for Implantable Medical Devices

https://poly-med.com/wp-content/uploads/2024/01/Fiber-1.png

2227

3361

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

poly-med2023-09-01 11:44:122024-01-24 17:53:20Bioresorbable Polymer Extrusions of Yarns, Fibers, & Films for Implantable Medical Devices https://poly-med.com/wp-content/uploads/2022/08/biomedical-textiles.jpg

185

369

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

poly-med2022-09-23 20:00:412024-01-17 09:26:24Absorbable Medical Devices as Implantable Tissue Scaffolds

https://poly-med.com/wp-content/uploads/2022/08/biomedical-textiles.jpg

185

369

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

poly-med2022-09-23 20:00:412024-01-17 09:26:24Absorbable Medical Devices as Implantable Tissue Scaffolds https://poly-med.com/wp-content/uploads/2020/02/purpleprene_0645.jpg

2402

3600

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

poly-med2022-09-07 20:45:282024-01-17 09:33:23Bioresorbable Polymers for Implantable Medical Devices

https://poly-med.com/wp-content/uploads/2020/02/purpleprene_0645.jpg

2402

3600

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

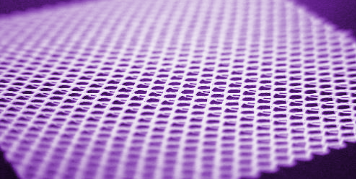

poly-med2022-09-07 20:45:282024-01-17 09:33:23Bioresorbable Polymers for Implantable Medical Devices https://poly-med.com/wp-content/uploads/2021/05/Image1.png

179

356

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

poly-med2022-08-15 19:09:002024-01-17 09:18:47Biomedical Textiles as Implantable Medical Devices

https://poly-med.com/wp-content/uploads/2021/05/Image1.png

179

356

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

poly-med2022-08-15 19:09:002024-01-17 09:18:47Biomedical Textiles as Implantable Medical Devices https://poly-med.com/wp-content/uploads/2022/02/shop-dioxaprene-100m-polymer-granules_large.jpeg

600

569

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

poly-med2022-07-15 23:06:002024-01-17 09:55:47Polydioxanone (PDO) Polymer for Bioresorbable Medical Devices

https://poly-med.com/wp-content/uploads/2022/02/shop-dioxaprene-100m-polymer-granules_large.jpeg

600

569

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

poly-med2022-07-15 23:06:002024-01-17 09:55:47Polydioxanone (PDO) Polymer for Bioresorbable Medical Devices https://poly-med.com/wp-content/uploads/2022/06/SEM-Image.jpg

284

348

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

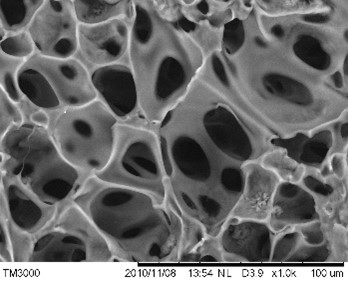

poly-med2022-06-29 15:14:092023-09-26 19:41:18Bioresorbable Polymer Foams as Medical Devices

https://poly-med.com/wp-content/uploads/2022/06/SEM-Image.jpg

284

348

poly-med

https://poly-med.com/wp-content/uploads/2023/06/poly-med-anniversary-logo-BLACK-300x77.png

poly-med2022-06-29 15:14:092023-09-26 19:41:18Bioresorbable Polymer Foams as Medical DevicesWe provide an adaptable approach to customer needs for any medical application. How can we help you?

Interested in learning about Poly-Med's bioresorbable polymer portfolio and processing capabilities? Complete this form to receive the catalog.

We provide an adaptable approach to customer needs for any medical application. How can we help you?

Please provide your name and email to view our ISO Certificate.

Please provide your name and email to view our Max-Prene® Polymer Data Sheet.

We provide an adaptable approach to customer needs for any medical application. How can we help you?

We provide an adaptable approach to customer needs for any medical application. How can we help you?

Please provide your name and email to view our Photoset® 311 Resin Data Sheet.

Please provide your name and email to view our Dioxaprene® Polymer Data Sheet.

Please provide your name and email to view our Glycoprene® Polymer Series Data Sheets.

Please provide your name and email to view our Lactoprene® Polymer Series Data Sheets.

Please provide your name and email to view our Aquaprene® Polymer Data Sheet.

Please provide your name and email to view our Lactoflex® 7415 3DP Filament Data Sheet.

Please provide your name and email to view our Dioxaprene® 100M 3DP Filament Data Sheet.

Please provide your name and email to view our Lactoprene® 100M 3DP Filament Data Sheet.

Please provide your name and email to view our Strataprene® 5525 3DP Filament Data Sheet.

Please provide your name and email to view our Caproprene® 100M 3DP Filament Data Sheet.

Please provide your name and email to view our Strataprene® Polymer Series Data Sheets.

Please provide your name and email to view our ISO Certificate.